Food waste is a global problem with significant environmental, economic, and social consequences. From overflowing landfills to wasted resources, the impact is far-reaching. This guide, “How to Manage Your Food Inventory to Reduce Waste,” is designed to equip you with the knowledge and tools to tackle this issue head-on, whether you’re managing a bustling restaurant, a cozy cafe, or your own kitchen.

We’ll delve into understanding the problem, assessing current practices, and implementing effective strategies. You’ll learn how to track inventory, optimize storage, plan menus, and leverage technology. This comprehensive approach empowers you to minimize waste, save money, and contribute to a more sustainable future.

Understanding Food Waste: The Problem and Its Impact

Food waste is a significant global issue with far-reaching consequences, impacting the environment, economy, and society. Understanding the problem and its various dimensions is crucial for developing effective strategies to reduce waste and promote sustainability. This section delves into the multifaceted impacts of food waste, exploring its environmental, economic, and social ramifications.

Environmental Consequences of Food Waste

Food waste contributes significantly to environmental degradation. From the resources used in food production to the waste disposal methods employed, the entire lifecycle has an environmental footprint.

- Greenhouse Gas Emissions: When food decomposes in landfills, it releases methane, a potent greenhouse gas that traps heat in the atmosphere. The production of food also requires energy for farming, processing, transportation, and storage, all of which contribute to greenhouse gas emissions. For instance, the Food and Agriculture Organization of the United Nations (FAO) estimates that approximately one-third of all food produced globally is wasted, contributing to around 8-10% of global greenhouse gas emissions.

- Resource Depletion: Producing food requires vast amounts of resources, including water, land, and energy. Wasting food means wasting these resources. For example, the water used to grow food that is ultimately wasted could be used for other purposes, like drinking water or irrigation. Similarly, land used for agriculture that produces wasted food could be used for other ecosystems, like forests.

- Landfill Overload: Landfills are often the final destination for food waste. The accumulation of food waste in landfills leads to increased land use and potential soil and water contamination. The decomposition of food waste can also leach harmful chemicals into the soil and groundwater.

- Deforestation: Increased demand for food production can lead to deforestation to create more farmland. The clearing of forests for agriculture destroys habitats and contributes to climate change.

Global Scale of Food Waste and Regional Differences

The scale of food waste varies across the globe, with significant differences between developed and developing countries. Understanding these regional disparities is crucial for implementing targeted waste reduction strategies.

- Global Statistics: As mentioned previously, approximately one-third of all food produced for human consumption globally is lost or wasted, equivalent to about 1.3 billion tonnes per year. This includes food lost at various stages, from production and harvest to processing, distribution, and consumption.

- Regional Differences:

- Developed Countries: In developed countries, a significant portion of food waste occurs at the consumer level, with households often discarding edible food due to factors like over-purchasing, poor storage practices, and confusion over date labels. Food waste is also significant at the retail level.

- Developing Countries: In developing countries, food waste often occurs at the production and processing stages due to inadequate infrastructure, lack of storage facilities, and poor transportation networks. Post-harvest losses, such as spoilage due to improper storage, are also a major issue.

- Examples: In North America and Europe, consumers account for a large share of food waste, while in Sub-Saharan Africa and South Asia, post-harvest losses are more prevalent.

Economic Impact of Food Waste on Consumers and Businesses

Food waste has significant economic implications for both consumers and businesses. Reducing food waste can lead to cost savings and improved financial efficiency.

- Impact on Consumers: Wasted food represents a direct financial loss for consumers. When food is thrown away, the money spent on purchasing it is also wasted.

For example, a household that throws away $50 worth of food per month is effectively losing $600 per year.

Reducing food waste allows consumers to save money and allocate their budgets more efficiently.

- Impact on Businesses: Food waste impacts businesses in several ways.

- Increased Costs: Businesses incur costs related to purchasing, storing, and disposing of food. Wasted food increases these costs.

- Reduced Profitability: Food waste reduces profitability by decreasing the amount of food available for sale.

- Operational Inefficiencies: Food waste can lead to operational inefficiencies, such as the need for more frequent deliveries and increased labor costs.

Reducing food waste allows businesses to improve their bottom line and operate more efficiently.

- Examples: Restaurants can reduce food waste by implementing portion control, optimizing inventory management, and training staff on proper food handling techniques. Grocery stores can reduce waste by implementing strategies like markdown pricing for items nearing their expiration dates and donating surplus food to food banks.

Social Implications of Food Waste, Including Food Insecurity

Food waste has significant social implications, particularly in relation to food insecurity and resource allocation.

- Food Insecurity: Food waste exacerbates food insecurity by reducing the overall food supply and increasing food prices.

Globally, millions of people face hunger and malnutrition, and reducing food waste could help to alleviate this problem.

By recovering and redistributing edible food that would otherwise be wasted, we can help feed those in need.

- Resource Allocation: Food waste represents a misallocation of resources. The resources used to produce wasted food could be used to produce food for those who need it.

- Ethical Considerations: Food waste raises ethical concerns about the responsible use of resources and the equitable distribution of food.

- Examples: Food banks and food rescue organizations play a vital role in collecting and distributing surplus food to people in need. By supporting these organizations and implementing food waste reduction strategies, we can help address food insecurity and promote a more equitable food system.

Assessing Your Current Inventory Management Practices

Understanding your current food inventory practices is the critical first step in reducing food waste. This assessment provides a baseline, allowing you to identify areas for improvement and track your progress over time. Without a clear understanding of your current situation, it’s impossible to implement effective strategies or measure their success. This section will guide you through the process of evaluating your inventory methods, pinpointing waste sources, and calculating the associated costs.

Tracking Food Purchases, Usage, and Disposal

Accurately tracking food purchases, usage, and disposal is essential for establishing a benchmark and understanding your current food waste patterns. This data provides the foundation for informed decision-making and allows you to identify the most significant contributors to waste within your operation.To effectively track this information, consider the following:

- Food Purchases: Maintain detailed records of all food purchases. This should include the date of purchase, the type of food, the quantity purchased (e.g., pounds, cases, units), the unit price, and the supplier.

- Food Usage: Monitor how food is used. This involves tracking what is used in recipes, sold to customers, or consumed by employees. Use standardized recipes and portion control guidelines to minimize overproduction.

- Food Disposal: Categorize and quantify food waste. This includes waste from preparation (e.g., vegetable scraps, trimmings), plate waste, expired food, and spoilage. Record the date of disposal, the type of food, the quantity disposed of (e.g., pounds, containers), and the reason for disposal. Consider using different waste streams (compost, landfill) to better track and analyze your disposal habits.

Regularly review this data to identify trends and patterns. For example, you might notice that a particular ingredient is consistently wasted, or that waste increases during specific days or times.

Auditing Current Practices and Identifying Waste Sources

Conducting a thorough audit of your current inventory management practices will help you identify specific areas where waste is occurring and pinpoint the root causes. This involves a systematic review of your entire food lifecycle, from receiving to disposal.The audit process can be broken down into these steps:

- Walk-Through and Observation: Conduct a physical walk-through of your food storage areas (pantry, refrigerator, freezer), preparation areas, and waste disposal areas. Observe employee practices, looking for potential waste-generating behaviors.

- Review of Records: Examine your purchase records, inventory logs, production sheets, and waste disposal records. Identify any discrepancies or inconsistencies in the data.

- Employee Interviews: Talk to your employees about their experiences and observations regarding food waste. They may have valuable insights into the causes of waste and potential solutions.

- Waste Stream Analysis: Physically examine your waste streams to determine the types and quantities of food being wasted. This can be done by sorting through waste bins or using a waste audit tool.

- Identify Waste Sources: Based on your observations, record reviews, and waste stream analysis, identify the primary sources of food waste in your operation. Common sources include:

- Overproduction

- Improper storage

- Poor inventory rotation (FIFO – First In, First Out)

- Poor portion control

- Spillage and spoilage

- Lack of menu planning

Calculating the Cost of Food Waste

Calculating the cost of food waste is crucial for understanding its financial impact and justifying the investment in waste reduction strategies. This calculation provides a clear picture of the financial losses associated with wasted food.To calculate the cost of food waste, use the following formula:

Cost of Food Waste = (Total Quantity of Food Wasted) x (Average Cost per Unit)

For example, if you waste 50 pounds of chicken breasts per month, and the average cost per pound is $3.00, the monthly cost of chicken waste is $150.00 (50 pounds x $3.00/pound).Beyond the direct cost of the food itself, also consider the indirect costs associated with food waste, such as:

- Labor Costs: The labor used to purchase, store, prepare, and dispose of wasted food.

- Energy Costs: The energy used to store and prepare wasted food.

- Disposal Costs: The costs associated with waste disposal, such as landfill fees or composting services.

By accurately calculating the cost of food waste, you can prioritize your waste reduction efforts and track the return on investment of your implemented strategies. A restaurant in San Francisco, for example, that implemented a food waste reduction program reported a 20% reduction in food waste and a corresponding 10% reduction in food costs within the first year, demonstrating the tangible financial benefits of these practices.

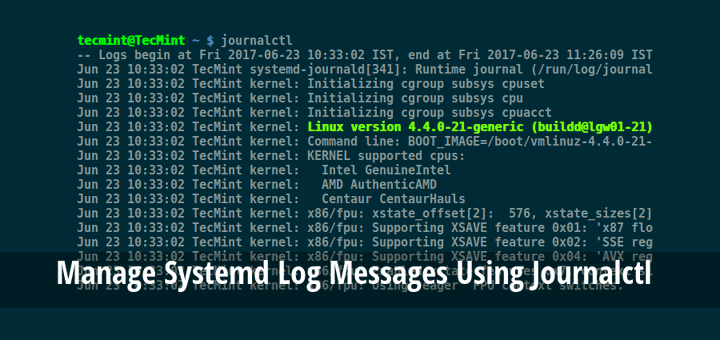

Implementing Effective Inventory Tracking Systems

Keeping track of your food inventory is crucial for minimizing waste. A well-structured system allows you to monitor what you have, how much of it, and when it’s likely to expire. This information empowers you to make informed decisions about what to use first, what to purchase, and ultimately, how to reduce the amount of food that ends up in the trash.

Let’s explore how to set up an effective inventory tracking system.

Designing an Inventory Tracking System: Digital vs. Manual Methods

There are primarily two approaches to tracking your food inventory: digital and manual. Both have their advantages and disadvantages, and the best choice for you will depend on your resources, the size of your inventory, and your personal preferences.Digital methods typically involve using software or spreadsheets. Manual methods rely on physical records, such as written lists or checklists. Consider your needs and the level of detail you require when choosing a method.

Comparing Inventory Tracking Methods: Pros and Cons

Choosing the right inventory tracking method requires understanding the benefits and drawbacks of each option. The following table provides a comparison of different methods:

| Tracking Method | Pros | Cons | Example |

|---|---|---|---|

| Spreadsheets (e.g., Google Sheets, Excel) |

|

|

Create columns for item name, quantity, purchase date, expiration date, and location. Use formulas to calculate days until expiration. |

| Inventory Management Software |

|

|

Software like Sortly, or FoodStorm offer features such as mobile scanning, automated ordering, and inventory tracking. |

| Manual Systems (e.g., Written Lists, Whiteboards) |

|

|

Use a whiteboard in your pantry or a notebook dedicated to inventory. List items, quantities, and expiration dates. |

| Combination of Methods |

|

|

Use a spreadsheet for detailed tracking and a whiteboard for quick visual reference of high-priority items nearing expiration. |

Ensuring Accuracy: Data Entry and Consistent Monitoring

The effectiveness of any inventory system hinges on accurate data entry and consistent monitoring. Without these, the system becomes unreliable and useless.

- Accurate Data Entry: When entering data, be meticulous. Double-check item names, quantities, purchase dates, and expiration dates. Consider using a barcode scanner (if applicable) to minimize errors.

- Consistent Monitoring: Regularly review and update your inventory. Establish a schedule for checking your stock, such as weekly or bi-weekly, depending on the turnover rate of your food.

- Training: If multiple people are involved in managing the inventory, ensure they are properly trained on how to use the system and enter data correctly.

Setting Up Expiration Date Alerts

One of the most valuable features of an inventory system is the ability to alert you when items are nearing their expiration dates. This allows you to prioritize using those items and reduce the risk of waste.Here’s how to set up expiration date alerts, depending on your chosen method:

- Spreadsheets: Use formulas (e.g., in Excel or Google Sheets) to calculate the number of days until an item expires. Then, use conditional formatting to highlight items that are nearing their expiration date (e.g., within a week or a month). For example, use the formula =IF(DATEDIF(TODAY(), E2, “d”)<30, “Expiring Soon”, “”) where E2 contains the expiration date.

- Inventory Management Software: Most software programs have built-in features for setting expiration date alerts. You can typically set a threshold (e.g., 30 days, 7 days) and receive notifications via email or within the software.

- Manual Systems: While manual systems lack automated alerts, you can create a system for regularly reviewing expiration dates. Dedicate a section of your inventory list to “Items Expiring Soon” and update it regularly.

By implementing these strategies, you can significantly improve your food inventory management and minimize waste.

The Power of FIFO (First-In, First-Out) and Other Rotation Strategies

Proper food rotation is a cornerstone of efficient food inventory management. Implementing effective rotation strategies helps minimize waste, maintain food quality, and ensure customer safety. Understanding and applying these techniques is crucial for any food service operation, from a small cafe to a large restaurant chain.

FIFO Method Explained

The FIFO method, or First-In, First-Out, is a fundamental inventory management technique. It prioritizes using the oldest inventory items first. This approach directly addresses the issue of food spoilage and waste by ensuring that products are consumed before they expire.The core principle of FIFO is simple:

- When new food items arrive, they are placed behind or below existing stock.

- Older items, those received earlier, are moved to the front or top, making them readily accessible for use.

- This ensures that the items with the shortest shelf life are used before they expire.

FEFO and Its Applications

While FIFO is widely used, another important strategy is FEFO, or First-Expired, First-Out. FEFO focuses on using items based on their expiration dates, regardless of when they were received. This is particularly important for items with variable shelf lives, such as produce or packaged goods with differing best-by dates.FEFO is often used in conjunction with FIFO. For instance:

- When receiving a shipment of canned goods, FIFO might be used within each product type (e.g., all tomato sauce cans).

- However, if some cans have a shorter “best by” date, FEFO would be applied to prioritize using those cans first, even if they were received at the same time as cans with a later date.

Effective Labeling and Organization

Proper labeling and organization are essential for successful food rotation. Clear, visible labels and a well-organized storage system make it easy to identify the oldest items and implement FIFO or FEFO.Here are some best practices:

- Date Labels: Always label food items with the date of receipt and, crucially, the expiration or “best by” date. Use a clear and consistent format for all labels. Consider using color-coded labels to easily distinguish between different types of products or dates.

- Storage Organization: Organize shelves and storage areas to facilitate FIFO/FEFO. Place new items behind or below older items. For example, when stocking shelves with milk cartons, place the newest cartons behind the older ones.

- Visual Aids: Utilize visual aids such as shelf dividers or designated areas for different “use by” dates. These tools help employees quickly identify and select the appropriate items.

- Rotation Charts: Use rotation charts or checklists to track inventory and ensure that items are being rotated properly. These can be simple spreadsheets or more sophisticated inventory management software.

For example, imagine a walk-in refrigerator. On the top shelf, you might store fresh produce. Each type of produce (e.g., lettuce, tomatoes) should be labeled with the date of arrival. As new produce arrives, it’s placed behind the existing stock. This setup allows staff to easily grab the oldest produce first.

Training Staff on Rotation Techniques

Training staff on proper rotation techniques is crucial for ensuring consistent implementation of FIFO and FEFO strategies.Here’s a breakdown of key training elements:

- Importance of Food Rotation: Explain the benefits of food rotation, including reduced waste, improved food quality, and enhanced food safety. Emphasize the cost savings associated with minimizing spoilage.

- FIFO/FEFO Principles: Provide clear instructions on how to apply FIFO and FEFO in different storage situations (refrigerators, freezers, dry storage). Use real-world examples and demonstrations.

- Labeling Procedures: Train staff on how to properly label food items with the date of receipt, expiration dates, and any other relevant information. Demonstrate the use of labeling equipment and explain the importance of legible labels.

- Storage Guidelines: Teach staff how to organize food items in storage areas to facilitate FIFO/FEFO. Explain the importance of keeping older items easily accessible and the proper placement of new inventory.

- Monitoring and Enforcement: Establish a system for monitoring and enforcing food rotation practices. This might involve regular inventory checks, spot inspections, and feedback to staff.

Training should be ongoing and reinforced regularly. Consider using visual aids, such as posters or checklists, to remind staff of the proper procedures. Regular reviews and updates to training materials ensure that everyone stays informed.

Optimizing Storage and Handling Procedures

Proper storage and handling are critical components of effective food inventory management, directly impacting food shelf life and minimizing waste. Implementing these practices safeguards food quality, reduces spoilage, and ultimately contributes to cost savings and environmental sustainability.

Role of Proper Storage Conditions

Maintaining optimal storage conditions is paramount to extending the shelf life of food products. Temperature, humidity, and light exposure significantly influence the rate of food degradation.* Temperature: Different foods require different temperature ranges for optimal preservation. Perishable items like meat, poultry, and dairy products must be stored at or below 40°F (4°C) to inhibit bacterial growth. Frozen foods should be kept at 0°F (-18°C) or below.

Fruits and vegetables also have specific temperature requirements, varying depending on the type. For example, bananas ripen faster at room temperature, while berries benefit from refrigeration.* Humidity: Humidity levels affect the moisture content of food, influencing its texture and susceptibility to spoilage. Dry storage areas are ideal for items like grains, pasta, and crackers, while high humidity can promote mold growth.

Conversely, excessive dryness can lead to dehydration and loss of quality in some produce.* Light Exposure: Exposure to light can degrade the quality of certain foods, particularly those containing fats and oils. Light can cause oxidation, leading to rancidity and flavor changes. Storing these items in dark, cool places helps preserve their quality.* Air Circulation: Adequate air circulation helps to maintain consistent temperatures and prevent moisture buildup, which can lead to spoilage.

Proper ventilation in storage areas is crucial, especially for produce.

Guidelines for Organizing Storage Areas

Organizing storage areas efficiently improves accessibility and visibility, making it easier to manage inventory and prevent waste. Effective organization also streamlines the First-In, First-Out (FIFO) method.* Designated Zones: Establish separate zones for different food categories, such as dry goods, refrigerated items, and frozen products. This prevents cross-contamination and makes it easier to locate specific items.* Clear Labeling: Label all items with their name, date of receipt, and any other relevant information, such as “use by” dates.

This helps employees quickly identify and rotate stock.* Shelving Systems: Utilize shelving systems that are easily accessible and allow for good air circulation. Shelves should be sturdy and adjustable to accommodate different sizes and types of products.* Visibility: Store items in a way that allows for easy visibility. Avoid stacking items too high, as this can make it difficult to see what is in stock and to rotate products properly.

Transparent containers are helpful for visibility.* Regular Inspections: Conduct regular inspections of storage areas to identify any signs of spoilage, pest infestation, or other problems. Remove any damaged or expired items immediately.

Importance of Proper Food Handling Practices

Proper food handling is essential to prevent spoilage and ensure food safety. Incorrect handling can lead to the growth of bacteria, mold, and other microorganisms, causing foodborne illnesses and waste.* Washing Hands: Wash hands thoroughly with soap and water before handling any food. This removes bacteria and other contaminants that could lead to spoilage.* Using Clean Utensils and Equipment: Use clean utensils, cutting boards, and other equipment when handling food.

Regularly sanitize these items to prevent cross-contamination.* Proper Thawing: Thaw frozen foods safely, either in the refrigerator, in cold water, or in the microwave (if the food will be cooked immediately). Avoid thawing foods at room temperature, as this can promote bacterial growth.* Cooking to Safe Temperatures: Cook foods to the appropriate internal temperatures to kill harmful bacteria.

Use a food thermometer to ensure that foods are cooked thoroughly.* Storing Cooked Foods Properly: Store cooked foods promptly in the refrigerator, within two hours of cooking. Use airtight containers to prevent contamination and drying out.

Tips for Preventing Cross-Contamination in Storage

Cross-contamination occurs when harmful bacteria or other microorganisms are transferred from one food item to another, potentially causing foodborne illness. Following these tips minimizes the risk of cross-contamination in storage.

- Separate Raw and Cooked Foods: Store raw meat, poultry, and seafood separately from cooked foods and ready-to-eat items. Place raw items on lower shelves to prevent drips from contaminating other foods.

- Use Separate Cutting Boards and Utensils: Dedicate separate cutting boards and utensils for raw and cooked foods. Wash and sanitize these items thoroughly after each use.

- Cover Foods: Cover all foods stored in the refrigerator to prevent cross-contamination and maintain moisture levels.

- Clean and Sanitize Storage Areas Regularly: Clean and sanitize storage areas regularly to eliminate any bacteria or other contaminants. This includes shelves, floors, and walls.

- Control Pests: Implement pest control measures to prevent rodents, insects, and other pests from contaminating food.

Menu Planning and Portion Control Strategies

Effective menu planning and portion control are crucial for minimizing food waste in any food service operation or home kitchen. By strategically planning meals and managing serving sizes, you can significantly reduce the amount of food that ends up discarded. This not only benefits the environment but also improves profitability by lowering food costs.

Menu Planning’s Role in Waste Reduction

Menu planning allows for a proactive approach to food waste management. It involves considering various factors, such as customer preferences, seasonal availability of ingredients, and the efficient use of ingredients across multiple dishes.

Analyzing Sales Data for Demand Prediction

Analyzing past sales data is a key step in predicting future demand and optimizing portion sizes. This involves tracking the popularity of different menu items and identifying trends.To analyze sales data effectively, follow these steps:

- Collect Historical Data: Gather sales records from at least the past several months, ideally a year, to account for seasonal variations.

- Categorize Menu Items: Group similar items together (e.g., appetizers, entrees, desserts) for easier analysis.

- Track Sales Volume: Record the number of each menu item sold during specific time periods (e.g., daily, weekly, monthly).

- Identify Peak Times: Determine the days and times with the highest customer traffic and sales.

- Calculate Average Sales: Compute the average number of each item sold over different time periods.

- Analyze Trends: Look for patterns in sales data, such as items that are consistently popular or those that have declining sales.

- Adjust Portion Sizes: Based on your analysis, adjust portion sizes to match demand, reducing waste from overproduction.

For example, a restaurant that consistently sells a large number of a particular pasta dish might increase the amount of pasta prepared. Conversely, if a side dish is frequently left uneaten, the portion size could be reduced.

Portion Control Techniques

Implementing portion control techniques is essential for preventing food waste. This involves using tools and methods to ensure consistent and appropriate serving sizes.Here are some portion control techniques:

- Use Standardized Serving Utensils: Employ scoops, ladles, and portioning spoons to measure servings of items like rice, mashed potatoes, and sauces.

- Pre-Portion Ingredients: Prepare ingredients in advance into individual portions, especially for items like salads, sandwiches, and desserts.

- Use Portion-Controlled Containers: Utilize containers with pre-marked fill lines or specific capacities for items like soups, stews, and beverages.

- Implement Visual Guides: Provide staff with visual guides, such as photographs or diagrams, showing the correct portion sizes for each menu item.

- Train Staff: Train kitchen staff on proper portioning techniques and the importance of adhering to standardized recipes.

For instance, when serving a steak, the restaurant might use a scale to ensure each steak is the correct weight, preventing waste from oversized portions.

Benefits of Standardized Recipes

Standardized recipes are a cornerstone of efficient food service operations, contributing significantly to waste reduction and cost control. They provide clear instructions and consistent results, making it easier to manage inventory and predict food needs.The benefits of standardized recipes include:

- Consistent Food Quality: Standardized recipes ensure that each dish is prepared consistently, meeting customer expectations.

- Accurate Ingredient Usage: Recipes specify exact ingredient quantities, minimizing waste from over-purchasing or incorrect measurements.

- Simplified Inventory Management: Standardized recipes make it easier to forecast ingredient needs and track inventory levels.

- Reduced Labor Costs: Recipes streamline the cooking process, reducing preparation time and labor costs.

- Improved Waste Control: By providing precise measurements, recipes help prevent overproduction and food waste.

For example, a bakery uses a standardized recipe for chocolate chip cookies. The recipe specifies the exact amount of flour, sugar, and chocolate chips needed for each batch, minimizing waste and ensuring consistent cookie quality.

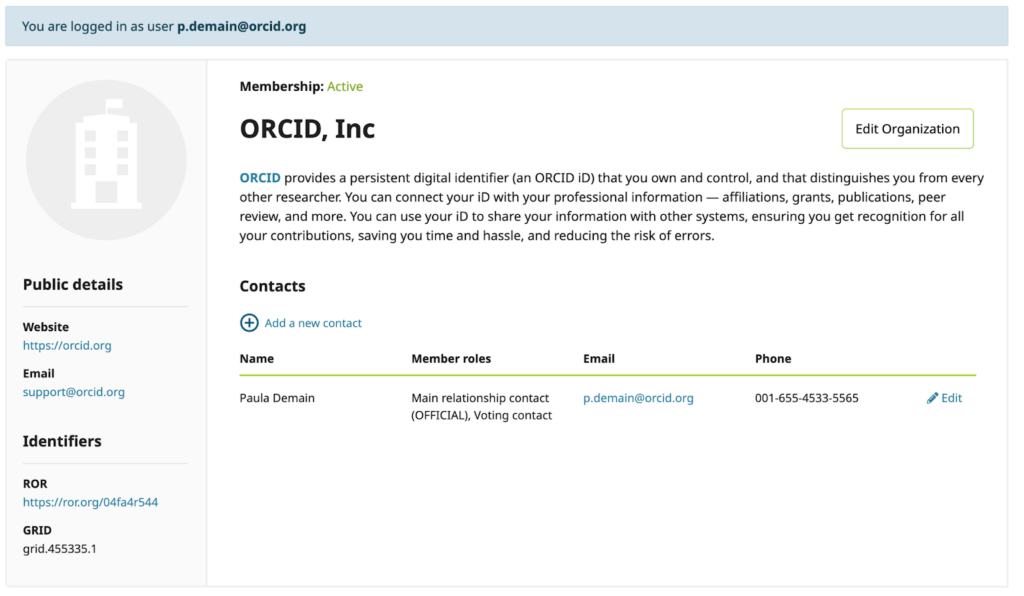

Leveraging Technology for Inventory Control

Implementing technology is a crucial step in modernizing food inventory management and significantly reducing waste. Utilizing software and hardware solutions streamlines processes, improves accuracy, and provides valuable data insights. This section explores how technology can transform your inventory practices, making them more efficient and sustainable.

Streamlining Inventory Tracking with Software

Inventory management software offers a centralized platform for tracking food items, providing real-time visibility into stock levels, expiration dates, and movement within your facility. This centralized approach eliminates the need for manual spreadsheets and reduces the risk of human error.Inventory management software typically offers the following features:

- Real-time Inventory Updates: Automatically updates stock levels as items are received, used, or discarded.

- Automated Ordering: Generates purchase orders based on pre-set reorder points, preventing stockouts and overstocking.

- Expiration Date Tracking: Monitors expiration dates and sends alerts to prevent spoilage and ensure FIFO (First-In, First-Out) rotation.

- Recipe Management: Integrates with recipe costing and menu planning to track ingredient usage and calculate food costs.

- Reporting and Analytics: Generates reports on inventory turnover, waste, and cost of goods sold, providing insights for informed decision-making.

Comparing Inventory Management Software Options

Several inventory management software options cater to different business sizes and needs. Evaluating the features, pricing, and compatibility of each option is crucial for selecting the right solution.Here’s a comparison of key features across various software options:

| Feature | Option A (Example: Simple Inventory) | Option B (Example: FoodStorm) | Option C (Example: MarketMan) |

|---|---|---|---|

| Pricing | Starts at $50/month | Custom pricing | Starts at $149/month |

| User Interface | User-friendly, basic | Advanced, customizable | Intuitive, cloud-based |

| Mobile Accessibility | Yes | Yes | Yes |

| Recipe Management | Limited | Extensive | Good |

| Supplier Management | Basic | Advanced | Good |

| Reporting | Standard | Comprehensive | Comprehensive |

| Integration | Limited | Good, POS and accounting | Good, POS and accounting |

Choosing the right software depends on factors such as budget, the complexity of your operations, and the level of integration required. Consider the long-term scalability of the software and the availability of customer support.

Utilizing Barcode Scanning and Other Technologies

Barcode scanning and other technologies significantly enhance inventory accuracy and efficiency. These tools minimize manual data entry, reducing errors and saving time.Here’s how these technologies are utilized:

- Barcode Scanning: Scans barcodes on incoming and outgoing food items to quickly update inventory levels. This technology eliminates the need for manual data entry, which reduces human error. For example, a restaurant can scan a case of tomatoes upon delivery, instantly updating the inventory count.

- RFID (Radio-Frequency Identification): Uses radio waves to track items wirelessly. RFID tags can be attached to food items, providing real-time location tracking. This technology is useful in large-scale operations where quick and accurate inventory counts are crucial.

- Digital Scales: Integrate with inventory software to automatically record the weight of food items. This is particularly useful for bulk ingredients and portion control.

- Temperature Sensors: Monitor the temperature of refrigerators and freezers to ensure food safety and prevent spoilage. Alerts can be sent if temperatures deviate from the recommended range.

These technologies streamline inventory processes, improving accuracy and providing real-time data for informed decision-making.

Integrating Technology with Existing Business Systems

Integrating inventory management technology with existing business systems is essential for maximizing its benefits. This integration allows for seamless data flow and eliminates the need for manual data transfer.Here’s how to integrate technology with existing systems:

- Point of Sale (POS) Systems: Integrate inventory software with your POS system to automatically deduct ingredients as menu items are sold. This integration provides real-time inventory updates and helps track food costs. For example, when a customer orders a pizza, the system automatically reduces the quantity of flour, cheese, and other ingredients in your inventory.

- Accounting Software: Integrate inventory software with your accounting software to streamline financial reporting and track the cost of goods sold (COGS). This integration helps you understand your food costs and identify areas for improvement.

- Supplier Portals: Connect with supplier portals to automate the ordering process and track deliveries. This integration streamlines communication with suppliers and reduces the risk of errors.

- Cloud-Based Solutions: Utilize cloud-based inventory management software to enable access to data from anywhere with an internet connection. This provides flexibility and allows for real-time collaboration.

By integrating technology with existing business systems, you create a more efficient and data-driven approach to food inventory management, ultimately reducing waste and improving profitability.

Collaboration and Communication for Waste Reduction

Reducing food waste isn’t a solo endeavor; it requires a team effort. Effective communication and collaboration across all departments, from the kitchen to the front of the house and even to suppliers, are essential for minimizing waste and maximizing efficiency. This section Artikels strategies for fostering a collaborative environment to achieve significant reductions in food waste.

Importance of Communication Between Staff

Clear and consistent communication is the cornerstone of any successful food waste reduction strategy. Each department plays a vital role, and when communication breaks down, waste increases.* Kitchen Staff: Kitchen staff are the primary handlers of food and are responsible for preparation, cooking, and portioning. They need to communicate:

- Daily production needs to the purchasing department.

- Information about spoilage, overproduction, and potential menu adjustments to the front-of-house staff.

- Feedback on the quality of ingredients and the efficiency of inventory rotation to the purchasing department.

Purchasing Department

The purchasing department manages the ordering of ingredients and needs to communicate:

- Inventory levels and upcoming needs to kitchen staff.

- Information about supplier lead times, availability of ingredients, and pricing fluctuations.

- Feedback on the quality and consistency of deliveries to suppliers.

Front-of-House Staff

Front-of-house staff interact directly with customers and can provide valuable insights. They need to communicate:

- Customer preferences, including popular and unpopular menu items, to the kitchen staff.

- Feedback on portion sizes and potential for customer requests to the kitchen staff.

- Information about daily specials and any changes to the menu to the kitchen and purchasing departments.

Establishing Clear Communication Channels

Establishing clear communication channels ensures that information flows smoothly and efficiently between departments. This can take many forms, but consistency and accessibility are key.* Daily Shift Meetings: Short, focused meetings at the beginning of each shift allow for quick updates on inventory levels, specials, customer feedback, and any potential issues. These meetings should be brief and action-oriented.

Whiteboards and Digital Displays

Whiteboards or digital displays in the kitchen and other key areas can be used to track inventory levels, daily specials, customer feedback, and waste data. These are visual reminders of key information.

Shared Digital Platforms

Utilize shared platforms such as cloud-based inventory management systems, messaging apps, or email groups to facilitate communication. These platforms can streamline communication and ensure that all relevant staff members have access to the same information.

Regular Departmental Meetings

Hold regular meetings between departments to discuss inventory, waste reduction strategies, and overall performance. These meetings provide an opportunity for deeper discussions and collaborative problem-solving.

Collaborating with Suppliers to Minimize Waste

Suppliers can play a significant role in reducing food waste. Collaboration with suppliers can lead to more efficient ordering, reduced spoilage, and optimized delivery schedules.* Negotiating Order Quantities: Work with suppliers to negotiate order quantities that match your needs and storage capacity. Consider ordering more frequently in smaller quantities to reduce the risk of spoilage.

Requesting Proper Packaging and Handling

Communicate your needs for proper packaging and handling to your suppliers to minimize damage during transit and storage.

Establishing Clear Delivery Schedules

Coordinate delivery schedules with your suppliers to ensure timely deliveries and avoid unnecessary storage and handling.

Exploring “Ugly” Produce Options

Some suppliers offer “ugly” produce, which is perfectly edible but may not meet aesthetic standards. These items are often available at a lower cost and can be incorporated into soups, sauces, or other dishes where appearance is less critical.

Building Strong Relationships

Cultivate strong relationships with your suppliers. Regular communication can lead to a better understanding of your needs and a willingness to collaborate on waste reduction initiatives.

Benefits of Employee Training and Awareness Programs

Employee training and awareness programs are essential for fostering a culture of waste reduction. When employees understand the importance of reducing waste and are equipped with the necessary skills, they are more likely to actively participate in waste reduction efforts.* Food Handling and Storage Training: Provide training on proper food handling and storage techniques to minimize spoilage. This includes training on FIFO (First-In, First-Out) rotation, proper refrigeration, and safe food temperatures.

Portion Control Training

Train staff on portion control techniques to minimize plate waste. This may involve using standardized portioning tools or providing visual guides.

Waste Tracking and Reporting

Train employees on how to track and report waste accurately. This data is essential for identifying areas for improvement and monitoring progress.

Menu Planning and Recipe Optimization

Provide training on menu planning and recipe optimization to reduce food waste. This may involve developing recipes that utilize leftover ingredients or adjusting recipes to use less of a particular ingredient.

Awareness Campaigns

Implement awareness campaigns to educate employees about the environmental and financial costs of food waste. This can include posters, presentations, and other visual aids.

Incentive Programs

Consider implementing incentive programs to reward employees for their efforts in reducing food waste. This could involve bonuses, recognition, or other forms of appreciation.

Dealing with Leftovers and Food Scraps

Reducing food waste doesn’t just stop at inventory management; it also involves what happens to the foodafter* it’s been cooked and served. Properly handling leftovers and food scraps can significantly minimize waste and even create new culinary experiences. This section focuses on strategies for maximizing the use of what’s already on hand, from delicious new meals to sustainable disposal methods.

Utilizing Leftovers Creatively

Leftovers are often seen as a last resort, but with a little creativity, they can become exciting and flavorful meals. Repurposing leftovers reduces waste and can save time and money.

- Transforming Dinner into Lunch: A roasted chicken can become chicken salad sandwiches, chicken tacos, or a topping for a salad. Leftover pasta can be turned into a frittata or a pasta salad.

- Embracing the “Everything But the Kitchen Sink” Approach: Combine various leftovers in a casserole, a stir-fry, or a soup. This is a great way to clear out the fridge and discover new flavor combinations.

- Freezing for Future Meals: Cooked grains, soups, stews, and even individual portions of meals can be frozen for later use. Proper labeling and dating are crucial for maintaining quality and preventing freezer burn.

- Reimagining Flavors: Leftover roasted vegetables can be pureed into a sauce for pasta or used as a base for a dip. Grilled meats can be added to salads or used in quesadillas.

Creative Uses for Common Food Scraps

Food scraps are often discarded, but many of them can be repurposed into delicious and nutritious dishes. Utilizing these scraps not only reduces waste but also adds flavor and depth to your cooking.

Here’s a table illustrating creative uses for common food scraps:

| Food Scrap | Creative Use | Example |

|---|---|---|

| Vegetable Scraps (onion skins, carrot tops, celery ends, etc.) | Vegetable Stock | Simmer scraps with water, herbs, and spices for a flavorful broth. |

| Fruit Peels and Cores | Infused Water or Vinegar | Use citrus peels to infuse water or create flavored vinegar for cleaning or cooking. Apple cores can be added to cider. |

| Meat Bones | Bone Broth | Slowly simmer bones with water, vegetables, and herbs to extract collagen and nutrients. |

| Herb Stems | Infused Oil or Vinegar | Infuse olive oil or vinegar with herb stems for added flavor. |

| Bread Crusts and Ends | Breadcrumbs or Croutons | Dry and process bread scraps into breadcrumbs or toast them for croutons. |

| Vegetable Greens (broccoli stems, beet greens, etc.) | Sauteed Greens or Added to Soups | Sauté greens with garlic and olive oil or add them to soups and stews. |

Composting and Other Waste Disposal Methods

Composting is a natural process that breaks down organic matter into nutrient-rich soil. It’s an environmentally friendly way to dispose of food scraps and other organic waste, reducing landfill waste and creating a valuable resource for gardening. Other waste disposal methods are also important for handling food waste effectively.

- Composting: This involves creating the right environment for organic materials to decompose.

- Anaerobic Digestion: A process where microorganisms break down organic matter in the absence of oxygen, producing biogas (a renewable energy source) and digestate (a nutrient-rich fertilizer). This method is often used on a larger, industrial scale.

- Landfill Disposal (as a last resort): While composting and anaerobic digestion are preferred, some food waste will inevitably end up in landfills. Proper disposal practices can still help minimize the environmental impact.

Establishing a Composting Program

Establishing a composting program, whether at home or at a larger scale, requires careful planning and execution. This will help transform food scraps into a valuable resource.

- Choosing a Composting Method: There are various methods, including backyard composting (using a bin or pile), vermicomposting (using worms), and municipal composting programs.

- Selecting a Location: Choose a location that is convenient, well-drained, and partially shaded. Consider the space available and the needs of the composting method.

- Building or Buying a Compost Bin: Compost bins help contain the composting process and keep the compost tidy.

- Gathering Materials: Composting requires a balance of “greens” (nitrogen-rich materials like food scraps and grass clippings) and “browns” (carbon-rich materials like dry leaves and shredded paper).

- Layering and Turning: Layer greens and browns, and turn the compost regularly (every few weeks) to aerate it and speed up decomposition.

- Monitoring Moisture and Temperature: Keep the compost moist but not waterlogged. The temperature should rise as the compost decomposes.

- Harvesting the Compost: Once the compost is dark, crumbly, and has an earthy smell (typically after several months), it’s ready to use.

Monitoring, Evaluation, and Continuous Improvement

Regularly monitoring and evaluating your inventory management practices is crucial for long-term success in reducing food waste. This process allows you to identify areas for improvement, track progress, and adapt your strategies to achieve optimal results. It involves a cyclical approach of data collection, analysis, action, and refinement.

Regularly Monitoring Inventory Data to Identify Trends

Consistent monitoring of your inventory data provides valuable insights into your food waste patterns and helps you spot areas needing attention. This involves collecting and analyzing key metrics to identify trends and make informed decisions.

- Data Collection: Establish a system for consistently collecting data on inventory levels, purchases, sales, and waste. This could involve using a spreadsheet, inventory management software, or a combination of methods.

- Key Metrics: Focus on tracking critical metrics such as:

- Food Waste Percentage: Calculate the percentage of food waste relative to total food purchased or sold.

- Inventory Turnover Rate: Determine how quickly your inventory is being used and replenished.

- Spoilage Rate: Measure the amount of food that spoils before being used.

- Cost of Waste: Calculate the financial impact of food waste.

- Data Analysis: Regularly analyze the collected data to identify trends and patterns. Look for:

- Seasonal Variations: Are there periods of higher or lower waste?

- Product-Specific Trends: Which items are most prone to waste?

- Correlation with Events: Does waste increase during specific events or promotions?

- Visualization: Use charts and graphs to visualize your data. This makes it easier to identify trends and communicate your findings. For example, a line graph could show the monthly food waste percentage over a year, clearly illustrating any upward or downward trends.

- Regular Reviews: Schedule regular reviews of your inventory data, such as weekly or monthly, to ensure you stay on track.

Evaluating the Effectiveness of Inventory Management Strategies

Evaluating the effectiveness of your inventory management strategies is vital to determine what’s working and what needs adjustment. This evaluation process helps you assess the impact of your implemented changes and make informed decisions for future improvements.

- Establish Baselines: Before implementing any new strategies, establish a baseline for your key metrics. This will serve as a point of comparison to measure the impact of your changes. For example, measure the current food waste percentage before implementing a new FIFO system.

- Implement Strategies: Implement your chosen inventory management strategies, such as FIFO, improved storage procedures, or menu planning adjustments.

- Track Metrics: Continue to track your key metrics, such as food waste percentage, inventory turnover rate, and cost of waste, after implementing your strategies.

- Compare Data: Compare your post-implementation data with your baseline data to determine the impact of your strategies. Did your food waste percentage decrease? Did your inventory turnover rate improve?

- Identify Correlations: Analyze the data to identify any correlations between your strategies and changes in your key metrics. For example, did implementing a new storage system lead to a decrease in spoilage?

- Document Results: Document your findings, including the strategies you implemented, the changes in your key metrics, and any observed correlations. This documentation will be valuable for future reference and for communicating your successes to stakeholders.

- Gather Feedback: Collect feedback from your staff on the effectiveness of your strategies. Are they finding the new procedures easy to follow? Are they seeing a positive impact?

Framework for Setting Goals and Measuring Progress in Waste Reduction

Setting clear goals and measuring your progress is essential for achieving significant waste reduction. A well-defined framework provides direction and accountability, ensuring you stay focused on your objectives.

- Define Specific, Measurable, Achievable, Relevant, and Time-bound (SMART) Goals:

- Specific: Clearly define what you want to achieve. Instead of “Reduce food waste,” aim for “Reduce food waste by 15%.”

- Measurable: Establish metrics to track your progress. Track your food waste percentage, cost of waste, or inventory turnover rate.

- Achievable: Set realistic goals that are challenging but attainable. Research industry benchmarks or analyze your historical data to set realistic targets.

- Relevant: Ensure your goals align with your overall business objectives. Waste reduction should contribute to profitability and sustainability.

- Time-bound: Set a timeframe for achieving your goals. For example, “Reduce food waste by 15% within the next six months.”

- Establish a Baseline: Before setting goals, establish a baseline for your key metrics. This will provide a starting point for measuring your progress.

- Develop a Plan: Artikel the strategies you will implement to achieve your goals. This could include implementing FIFO, improving storage procedures, or adjusting menu planning.

- Monitor Progress: Regularly monitor your key metrics and track your progress toward your goals. Use charts and graphs to visualize your data and identify any deviations from your plan.

- Regularly Review and Adjust: Schedule regular reviews of your progress. If you are not meeting your goals, adjust your strategies or your timeline.

- Celebrate Successes: Acknowledge and celebrate your successes to motivate your team and reinforce the importance of waste reduction.

Methods for Making Adjustments to Inventory Management Practices Based on Performance Data

Analyzing performance data and making informed adjustments is essential for continuous improvement. This iterative process ensures that your inventory management practices remain effective and adaptable to changing circumstances.

- Analyze Data to Identify Areas for Improvement: Review your performance data to pinpoint specific areas where your inventory management practices are falling short. For example, if your spoilage rate is high for a particular product, investigate the causes.

- Identify Root Causes: Determine the underlying reasons for any identified problems. For example, if food is spoiling quickly, consider:

- Incorrect storage temperatures.

- Improper handling procedures.

- Inaccurate forecasting.

- Develop and Implement Corrective Actions: Based on your analysis, develop and implement corrective actions to address the root causes of your problems. For example, if incorrect storage temperatures are causing spoilage, recalibrate your refrigeration units.

- Monitor the Impact of Changes: After implementing corrective actions, continue to monitor your key metrics to assess the impact of the changes. Did your spoilage rate decrease after recalibrating your refrigerators?

- Iterate and Refine: The process of monitoring, evaluating, and adjusting is iterative. Continuously refine your inventory management practices based on your performance data.

- Seek Feedback: Solicit feedback from your staff to gain insights into the effectiveness of your changes. Their observations can provide valuable information for further improvements.

- Stay Informed: Keep up-to-date with industry best practices and new technologies that can enhance your inventory management efforts. For instance, explore advanced inventory management software that offers real-time tracking and forecasting capabilities.

Concluding Remarks

In conclusion, managing your food inventory to reduce waste is a journey of continuous improvement. By implementing the strategies Artikeld in this guide – from mastering FIFO to embracing technology and fostering collaboration – you can significantly reduce waste, boost your bottom line, and make a positive impact on the environment. Embrace these practices, and you’ll not only save resources but also contribute to a more sustainable future for everyone.

Remember, every step counts, and the journey begins with the choices you make today.