Understanding how to properly dispose of grease and wastewater is essential for protecting our environment and maintaining public health. Improper disposal can lead to a cascade of problems, from clogged pipes and sewer backups to water contamination and environmental damage. This guide will walk you through the critical steps needed to manage grease and wastewater responsibly.

We’ll explore the impact of improper disposal, identify common sources, and delve into effective disposal methods for both residential and commercial settings. From the “can and cool” method for home cooks to the complexities of grease traps and wastewater treatment plants, you’ll gain the knowledge to make informed decisions and contribute to a cleaner, healthier future.

The Importance of Proper Grease and Wastewater Disposal

Improper disposal of grease and wastewater poses significant threats to the environment, public health, and legal compliance. Understanding the correct methods for handling these substances is crucial for protecting our resources and avoiding negative consequences. This guide will Artikel the environmental, health, and legal implications of improper disposal.

Environmental Impact of Improper Disposal

Incorrect disposal practices can severely damage ecosystems. When grease and wastewater are improperly disposed of, they contaminate water sources and harm wildlife.

- Water Contamination: Grease and wastewater often contain harmful chemicals, such as oil, detergents, and food particles. These contaminants can seep into groundwater, polluting drinking water supplies and harming aquatic life. The EPA estimates that a single gallon of oil can contaminate up to a million gallons of water.

- Soil Contamination: When grease and wastewater are disposed of on land, they can contaminate the soil, making it unsuitable for plant growth and potentially leaching into groundwater.

- Damage to Wildlife: Wildlife can be directly affected by grease and wastewater. Birds and animals can become coated in oil, leading to hypothermia, starvation, and death. Aquatic life is also vulnerable, as pollutants can disrupt their habitats and food sources.

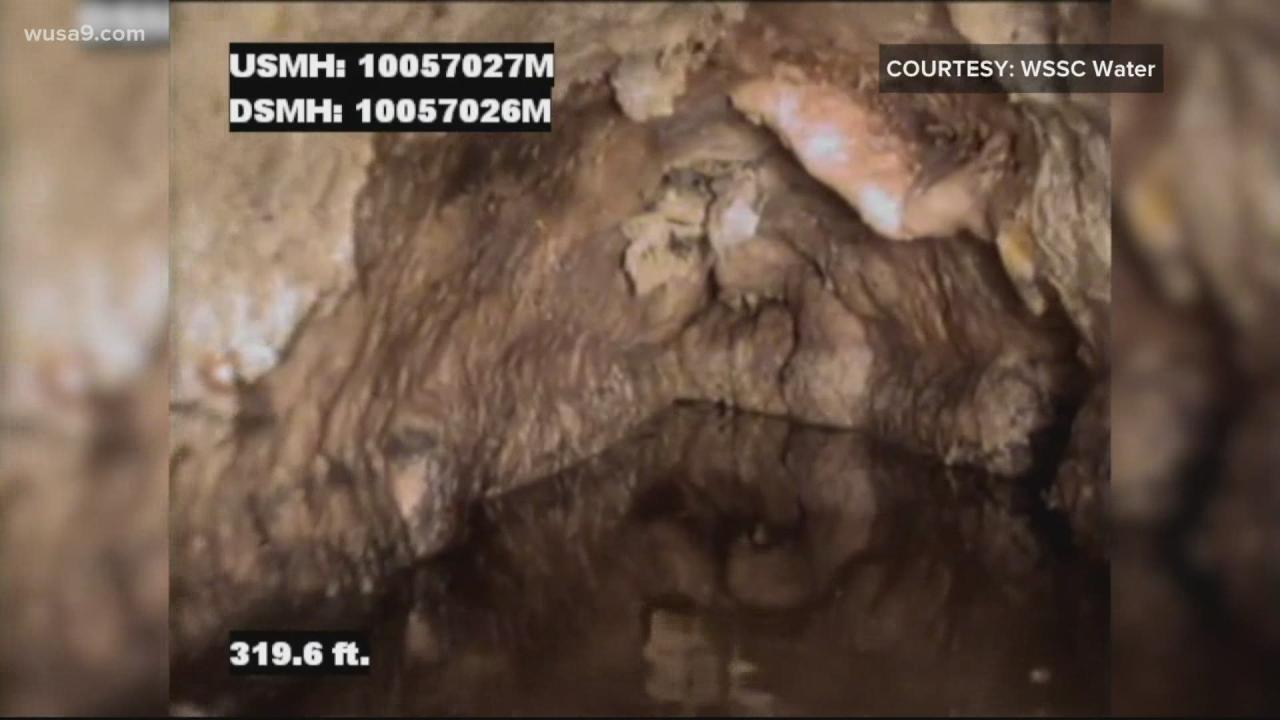

- Clogging of Infrastructure: Grease, in particular, solidifies and clogs sewer lines, leading to overflows that release untreated wastewater into the environment.

Common Problems Caused by Incorrect Disposal Methods

Improper disposal methods frequently lead to a variety of practical problems, including damage to infrastructure and financial burdens.

- Sewer Blockages: Grease, especially when poured down drains, solidifies and accumulates in sewer pipes. This can lead to blockages, resulting in sewage backups in homes and businesses.

- Wastewater Treatment Plant Overloads: When excessive grease and wastewater enter treatment plants, they can overload the system’s capacity. This can lead to inefficient treatment, and untreated wastewater being released into the environment.

- Increased Maintenance Costs: Blockages and system overloads necessitate costly repairs and increased maintenance efforts for municipalities and wastewater treatment facilities.

- Public Health Concerns: Sewage backups and overflows can expose the public to harmful bacteria and viruses, increasing the risk of illness.

Legal and Regulatory Consequences of Improper Disposal

Improper disposal of grease and wastewater is subject to a range of legal and regulatory consequences, varying by jurisdiction.

- Fines and Penalties: Violators may face significant fines and penalties, which can vary depending on the severity of the offense and the local regulations.

- Legal Action: Businesses and individuals may be subject to legal action from government agencies or other parties affected by the improper disposal.

- Permit Revocation: Businesses that handle grease and wastewater, such as restaurants and food processing facilities, may have their permits revoked if they fail to comply with disposal regulations.

- Environmental Remediation Costs: Responsible parties may be required to pay for the cleanup and remediation of any environmental damage caused by their improper disposal practices. For example, a business that improperly disposes of oil may be liable for the cost of cleaning up contaminated soil and water.

Potential Health Risks Associated with Mishandling Grease and Wastewater

Improper handling of grease and wastewater poses significant health risks to both individuals and the community.

- Exposure to Harmful Bacteria and Viruses: Wastewater often contains bacteria, viruses, and other pathogens that can cause various illnesses, including gastroenteritis, hepatitis, and respiratory infections.

- Skin and Eye Irritation: Contact with grease and wastewater can cause skin and eye irritation due to the presence of detergents, chemicals, and other irritants.

- Respiratory Problems: Inhaling fumes from wastewater can lead to respiratory problems, especially for individuals with asthma or other respiratory conditions.

- Spread of Disease: Improperly disposed of wastewater can attract disease-carrying vectors, such as mosquitoes and rodents, increasing the risk of disease transmission. For instance, standing water from sewage backups can become a breeding ground for mosquitoes, increasing the risk of West Nile virus.

Identifying Grease and Wastewater Sources

Understanding where grease and wastewater originate is the first step towards proper disposal. This knowledge helps in implementing effective strategies to prevent clogs, protect the environment, and comply with regulations. Identifying sources also aids in determining the appropriate treatment and disposal methods.

Common Residential Grease Sources

Grease in residential settings primarily comes from food preparation and cleaning activities. It’s crucial to be aware of these sources to avoid common plumbing issues.

- Cooking Oils and Fats: Used for frying, sautéing, and baking. These include vegetable oils (e.g., canola, olive), animal fats (e.g., lard, tallow), and butter.

- Food Scraps: Pieces of food, such as meat trimmings, cheese, and sauces, that contain fats and oils. These are often washed down the drain during dishwashing.

- Dairy Products: Milk, cream, and yogurt, while not entirely grease, contribute fats that can solidify and cause problems.

- Prepared Foods: Leftover sauces, gravies, and dressings, often discarded after a meal.

- Dishwashing: Washing dishes, pots, and pans, especially after cooking greasy foods. The use of dish soap emulsifies the grease temporarily, but it can still solidify in pipes.

Commercial Establishments Generating Significant Wastewater

Commercial establishments, particularly those involved in food service, generate large volumes of wastewater containing significant amounts of grease. These businesses must implement robust grease management systems.

- Restaurants: Restaurants of all types, from fast food to fine dining, are major grease producers. Frying, grilling, and food preparation processes generate substantial amounts of wastewater.

- Cafeterias and Caterers: Large-scale food service operations, such as school cafeterias, hospitals, and catering businesses, create significant wastewater volumes.

- Food Processing Plants: Facilities that process food products, such as meatpacking plants, produce plants, and bakeries, generate wastewater containing grease and other organic matter.

- Bakeries: Bakeries use oils and fats in baked goods and generate wastewater from cleaning and washing.

- Butcher Shops and Meat Markets: These establishments produce wastewater containing animal fats from cutting and preparing meats.

Types and Properties of Grease

Grease can be classified based on its origin and composition, influencing its behavior and the challenges it presents. Understanding these differences is vital for effective management.

- Animal Fats: Derived from animal sources, such as beef, pork, and poultry. They are typically solid at room temperature and have a higher melting point than vegetable oils. They tend to solidify more quickly in pipes, leading to clogs.

- Vegetable Oils: Extracted from plants, such as soybeans, corn, and sunflowers. They are generally liquid at room temperature but can solidify when cooled. They may contain a higher percentage of unsaturated fats compared to animal fats.

- Mineral Oils: Derived from petroleum. They are not typically used in food preparation but may be found in some industrial applications.

- Mixtures: Wastewater often contains a mixture of different types of grease, making it complex to manage.

Important Note: The solidification temperature of grease is a critical factor. Animal fats, with their higher saturated fat content, solidify more readily and can cause more severe blockages.

Categorizing Wastewater Based on Source and Composition

A systematic approach to categorizing wastewater aids in designing appropriate treatment and disposal strategies. This categorization is vital for regulatory compliance and effective waste management.

| Category | Source | Typical Composition | Management Considerations |

|---|---|---|---|

| Restaurant Wastewater | Restaurants, Cafes | High in animal fats, vegetable oils, food scraps, detergents. | Grease traps, regular cleaning, proper disposal of collected grease. |

| Food Processing Wastewater | Meatpacking plants, canneries | High in animal fats, vegetable solids, organic matter, and cleaning agents. | Pre-treatment systems, wastewater treatment plants (WWTPs), and potential for anaerobic digestion. |

| Residential Wastewater | Homes, apartments | Mixture of cooking oils, food scraps, soaps, and detergents. | Education on proper disposal methods, encouraging the use of grease interceptors in multi-unit dwellings. |

| Industrial Wastewater | Manufacturing facilities | May contain various types of oils, depending on the industrial process. | Specific pre-treatment and wastewater treatment tailored to the type of industrial process. |

Methods for Residential Grease Disposal

Properly disposing of grease at home is crucial to prevent clogged drains, protect local water systems, and avoid environmental harm. Several methods exist for safely and effectively handling cooking grease in your household.

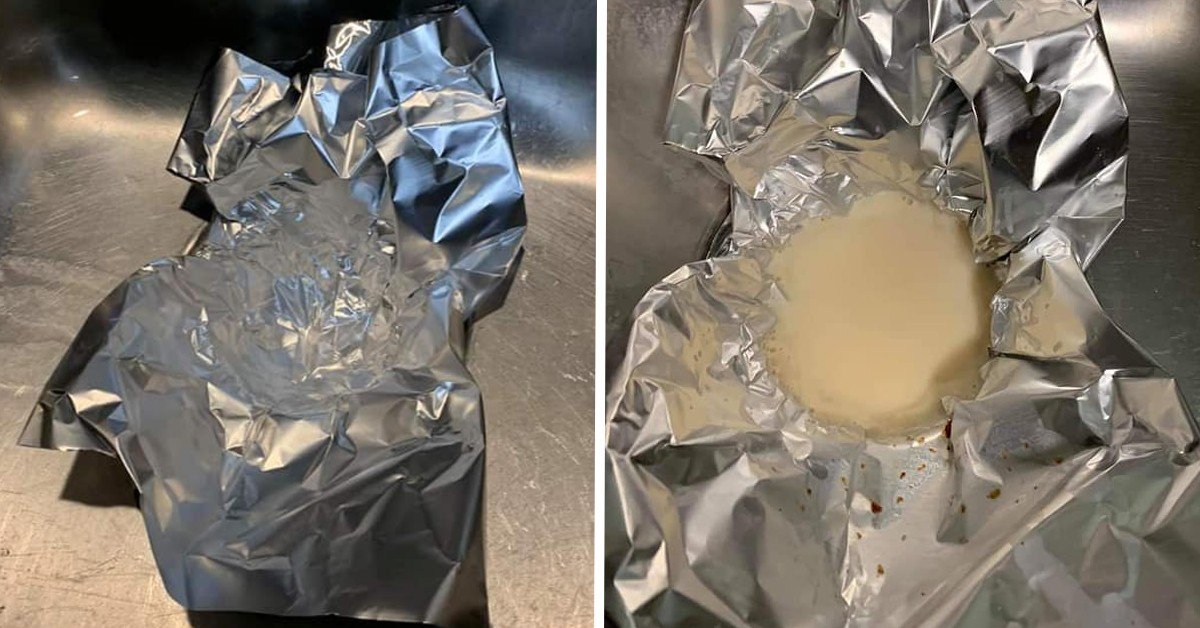

The “Can and Cool” Method for Grease Disposal

The “can and cool” method is a straightforward approach to grease disposal. It involves allowing the grease to cool and solidify before discarding it.

Steps for the “Can and Cool” Method:

- Allow Grease to Cool: After cooking, let the grease cool completely. Avoid pouring hot grease down the drain, as it can damage pipes and solidify further down the line, leading to blockages.

- Pour into a Container: Once cooled, carefully pour the grease into a non-recyclable container, such as an empty can (coffee, soup, etc.) or a disposable plastic container.

- Seal and Dispose: Seal the container tightly and dispose of it in the trash. Do not put it in the recycling bin.

Using Absorbent Materials to Solidify Grease

Using absorbent materials is another effective way to solidify grease before disposal. This method is particularly useful for smaller amounts of grease or when you have already poured the grease into a container.

Common absorbent materials include:

- Paper Towels: Paper towels are a readily available option. Simply wipe up the grease from the pan or container with paper towels and dispose of them in the trash.

- Coffee Grounds: Used coffee grounds can absorb grease. Mix the coffee grounds with the grease in the pan and allow it to cool and solidify before disposal.

- Cat Litter: Unused cat litter can be used to absorb grease. Add the litter to the cooled grease, mix well, and dispose of it in the trash.

Preventing Grease Buildup in Kitchen Drains

Preventing grease buildup is as important as proper disposal. Implementing preventive measures can significantly reduce the risk of drain clogs and costly plumbing repairs.

Consider these strategies:

- Wipe Dishes Before Washing: Before washing dishes, wipe off excess grease and food scraps with a paper towel and dispose of them in the trash.

- Use a Drain Strainer: Install a drain strainer in your kitchen sink to catch food particles and prevent them from entering the drain. Empty the strainer regularly.

- Avoid Pouring Grease Down the Drain: Never pour grease, oil, or fatty foods down the drain. This includes cooking oils, sauces, and meat drippings.

- Flush Drains with Hot Water (Sparingly): After washing dishes, flush the drain with hot (but not boiling) water to help wash away any residual grease. Avoid doing this excessively, as it can sometimes cause pipes to expand and contract, potentially leading to cracks over time.

Proper Use of Drain Strainers and Preventative Measures

Drain strainers are essential tools for preventing grease and food particles from entering the drain system. Using them correctly is key to their effectiveness.

Proper use includes:

- Choosing the Right Strainer: Select a drain strainer that fits your sink drain. Consider a fine-mesh strainer to catch even small particles.

- Regular Cleaning: Empty the strainer after each use or as needed. Dispose of the collected food scraps and grease in the trash.

- Inspect and Replace: Regularly inspect the strainer for damage. Replace it if it’s torn or damaged to ensure it continues to function effectively.

- Combined Approach: Using a drain strainer is most effective when combined with other preventative measures, such as wiping dishes and avoiding pouring grease down the drain.

Residential Grease Disposal Methods

Here’s a 3-column table summarizing different methods for residential grease disposal:

| Method | Description | Advantages |

|---|---|---|

| Can and Cool Method | Pour cooled grease into a non-recyclable container (e.g., can) and dispose of in the trash. | Simple, effective, and prevents drain clogs. |

| Absorbent Materials | Use absorbent materials (paper towels, coffee grounds, cat litter) to solidify grease before disposal in the trash. | Useful for small amounts of grease and cleaning up spills. |

| Preventative Measures | Wipe dishes before washing, use drain strainers, and avoid pouring grease down the drain. | Reduces grease buildup, minimizes drain clogs, and protects the environment. |

Methods for Commercial Wastewater Disposal

Commercial establishments, particularly those in the food service industry, generate significantly more wastewater and grease than residential properties. Proper disposal is crucial to prevent environmental damage, comply with local regulations, and maintain a functional and efficient wastewater system. This section details the methods used for commercial wastewater disposal, focusing on grease traps, maintenance, waste haulers, and regulatory compliance.

Grease Traps and Interceptors in Commercial Kitchens

Grease traps and interceptors are essential components of commercial wastewater systems, specifically designed to remove grease, oil, and solids from wastewater before it enters the public sewer system. These devices are strategically placed in commercial kitchens to capture these substances, preventing them from clogging pipes and causing operational issues.* Grease Traps: Generally smaller in size and used for lower-volume wastewater flows, often found under sinks or in dishwashing areas.

They are typically used in smaller establishments like cafes or small restaurants.* Grease Interceptors: Larger and more robust than grease traps, designed for high-volume wastewater flows. They are usually installed outside the building, underground, and are common in larger restaurants, hotels, and food processing facilities. They have a larger capacity to handle higher volumes of wastewater and collect more grease and solids.These devices work on the principle of gravity separation.

Wastewater enters the trap or interceptor, where the cooler temperature allows grease and oil to solidify and float to the surface, while solids settle at the bottom. The cleaner water then flows out to the sewer system. The efficiency of the trap or interceptor depends on its size, design, and maintenance. A properly sized and maintained system is crucial for optimal performance.

For example, a restaurant serving 200 meals per day would require a larger interceptor than a small coffee shop.

Grease Trap Cleaning and Maintenance

Regular cleaning and maintenance of grease traps and interceptors are critical for their effective operation and compliance with regulations. Neglecting maintenance can lead to clogs, backups, and potential fines.* Frequency of Cleaning: The frequency of cleaning depends on the size of the trap or interceptor, the volume of wastewater generated, and the amount of grease and solids produced. Most jurisdictions require cleaning at least quarterly, but some may require monthly or even more frequent cleaning, depending on the establishment’s specific circumstances.

A restaurant with a high volume of fried food sales will likely need more frequent cleaning than a bakery.* Cleaning Process: Cleaning typically involves removing the accumulated grease, oil, and solids from the trap or interceptor. This is usually done by a licensed waste hauler. The process involves pumping out the contents of the trap or interceptor and disposing of them properly at a permitted facility.

The trap or interceptor is then cleaned, inspected, and may be refilled with water.* Maintenance Tasks: Regular maintenance includes inspecting the trap or interceptor for leaks, damage, and proper operation. It also involves checking for any unusual odors or blockages. Regular maintenance helps prevent problems before they escalate.* Record Keeping: Maintaining detailed records of cleaning and maintenance activities is essential for compliance with regulations.

These records should include the date of cleaning, the name of the waste hauler, and the amount of waste removed.

Role of a Licensed Waste Hauler

Using a licensed waste hauler is a critical aspect of commercial wastewater disposal. Licensed haulers are trained and equipped to properly remove, transport, and dispose of grease trap waste in accordance with local, state, and federal regulations.* Compliance with Regulations: Licensed waste haulers ensure compliance with all applicable regulations regarding the transportation and disposal of grease trap waste. They are familiar with the specific requirements of the local jurisdiction and ensure that all waste is disposed of at a permitted facility.* Proper Equipment and Training: Licensed haulers use specialized equipment, such as vacuum trucks, to remove the waste from the grease trap or interceptor.

They also have the training and expertise to handle the waste safely and efficiently.* Waste Disposal at Permitted Facilities: Licensed haulers dispose of the waste at permitted facilities, such as wastewater treatment plants or rendering plants. These facilities are equipped to process the waste properly and prevent environmental contamination.* Documentation and Reporting: Licensed haulers provide documentation of the cleaning and disposal process, including manifests and disposal receipts.

This documentation is essential for compliance and record-keeping purposes.

Regulations for Discharging Wastewater into Public Sewer Systems

Commercial establishments must comply with local regulations regarding the discharge of wastewater into public sewer systems. These regulations are designed to protect the sewer system and the environment.* Permitting Requirements: Many jurisdictions require commercial establishments to obtain permits for discharging wastewater into the public sewer system. These permits may specify the types of wastewater that can be discharged, the limits on pollutants, and the monitoring requirements.* Grease and Oil Limits: Regulations typically set limits on the amount of grease and oil that can be discharged into the sewer system.

These limits are designed to prevent the buildup of grease and oil in the pipes, which can lead to clogs and sewer overflows.* Monitoring and Reporting: Commercial establishments may be required to monitor their wastewater and report the results to the local authorities. This may involve collecting samples and testing them for grease, oil, and other pollutants.* Penalties for Non-Compliance: Failure to comply with wastewater discharge regulations can result in penalties, including fines and the suspension of permits.

In severe cases, non-compliance can lead to legal action.

Best Practices for Commercial Wastewater Disposal

Implementing best practices is essential for effective and compliant commercial wastewater disposal.* Install and Maintain Grease Traps/Interceptors: Properly size, install, and maintain grease traps or interceptors to effectively remove grease and solids from wastewater. Ensure regular cleaning and maintenance.* Train Employees: Train employees on proper food handling practices, including scraping food scraps into the trash before washing dishes and not pouring grease down drains.

This reduces the amount of grease entering the wastewater system.* Use a Licensed Waste Hauler: Contract with a licensed waste hauler for regular cleaning and disposal of grease trap waste.* Follow Cleaning Schedules: Adhere to a regular cleaning schedule for grease traps and interceptors, based on the establishment’s needs and local regulations.* Keep Records: Maintain detailed records of all cleaning and maintenance activities, including the date, the name of the waste hauler, and the amount of waste removed.* Monitor Wastewater: Regularly monitor wastewater for grease, oil, and other pollutants, as required by local regulations.* Report Violations: Immediately report any violations of wastewater discharge regulations to the appropriate authorities.* Consider Alternatives: Explore alternative wastewater disposal methods, such as recycling grease for biofuel production, if feasible.

Wastewater Treatment Options

Wastewater treatment is a critical process for protecting public health and the environment. It involves a series of steps designed to remove contaminants from wastewater, making it safe for reuse or discharge back into the environment. Understanding these processes and technologies is essential for effective grease and wastewater management.

Primary and Secondary Wastewater Treatment Processes

The treatment of wastewater typically involves two main stages: primary and secondary treatment. Each stage focuses on removing different types of pollutants.Primary treatment is the first step in the wastewater treatment process. Its primary goal is to remove large solids and settleable materials from the wastewater. This stage typically involves:

- Screening: Wastewater initially passes through screens to remove large debris such as trash, rags, and other bulky items.

- Grit Removal: The wastewater then flows through grit chambers, where heavier materials like sand, gravel, and grit settle out. This prevents damage to downstream equipment.

- Sedimentation (Clarification): Wastewater is held in large sedimentation tanks, where gravity causes heavier solids to settle to the bottom as sludge. This sludge is then removed.

Secondary treatment follows primary treatment and focuses on removing dissolved organic matter and other pollutants that were not removed in the primary stage. This is often achieved through biological processes.

- Aeration: Wastewater is aerated to introduce oxygen, which supports the growth of microorganisms.

- Biological Treatment: Microorganisms, such as bacteria, consume organic matter in the wastewater. Common methods include:

- Activated Sludge: Wastewater is mixed with a culture of microorganisms in an aeration tank. The microorganisms consume the organic matter, forming a biomass that settles out.

- Trickling Filters: Wastewater is sprayed over a bed of media (e.g., rocks, plastic) on which microorganisms grow. These microorganisms consume the organic matter.

- Lagoons: Wastewater is held in large ponds, where natural processes and microorganisms treat the wastewater.

- Secondary Clarification: After biological treatment, the wastewater flows to a secondary clarifier, where the microorganisms and any remaining solids settle out.

Different Technologies Used in Wastewater Treatment Plants

Wastewater treatment plants utilize a variety of technologies to effectively remove pollutants. These technologies can be broadly categorized by the stage of treatment in which they are employed.For primary treatment:

- Bar Screens: These are used to remove large debris. They consist of a series of parallel bars that trap solid objects.

- Grit Chambers: These are designed to slow down the flow of wastewater, allowing heavier inorganic particles to settle out.

- Primary Sedimentation Tanks: Large tanks where wastewater is held for a period of time, allowing solids to settle to the bottom. Sludge is then removed from the bottom.

For secondary treatment:

- Aeration Systems: These systems introduce oxygen into the wastewater to support the growth of microorganisms. They can include:

- Diffused Aeration: Air is pumped through diffusers in the aeration tank, creating bubbles that dissolve oxygen in the water.

- Mechanical Aerators: These devices use rotating impellers to mix air and water.

- Activated Sludge Systems: These systems use a mixture of microorganisms and wastewater to treat organic pollutants.

- Trickling Filters: These systems use a bed of media on which microorganisms grow. Wastewater is sprayed over the media, and the microorganisms consume the organic pollutants.

- Membrane Bioreactors (MBRs): MBRs combine biological treatment with membrane filtration to remove pollutants.

Tertiary treatment technologies, which are employed after secondary treatment to further purify the wastewater, include:

- Filtration: Removes remaining suspended solids using sand filters, cloth filters, or other filtration media.

- Disinfection: Kills pathogens using chlorine, ultraviolet (UV) light, or ozone.

- Nutrient Removal: Processes like biological nutrient removal (BNR) and chemical precipitation remove excess nutrients like nitrogen and phosphorus.

The Role of Microorganisms in Breaking Down Grease

Microorganisms play a crucial role in the breakdown of grease and other organic matter in wastewater treatment. These microscopic organisms, including bacteria, fungi, and protozoa, use grease as a food source, breaking it down into simpler substances.The process of grease degradation by microorganisms involves several steps:

- Adsorption: Microorganisms attach to the grease particles.

- Enzyme Production: Microorganisms secrete enzymes, such as lipases, which break down the grease molecules into smaller components (fatty acids and glycerol).

- Consumption: The microorganisms then consume these smaller components as a source of energy and nutrients.

- Conversion: The microorganisms convert the grease into carbon dioxide, water, and new biomass.

The effectiveness of grease degradation depends on several factors:

- Type of Microorganisms: Different types of microorganisms are better at breaking down different types of grease.

- Oxygen Availability: Aerobic microorganisms require oxygen to thrive and break down grease efficiently.

- Temperature: The optimal temperature range for microbial activity is usually between 20°C and 30°C.

- pH: A neutral pH (around 7) is generally preferred for optimal microbial activity.

- Nutrient Availability: Microorganisms require essential nutrients, such as nitrogen and phosphorus, to grow and break down grease.

Environmental Benefits of Wastewater Treatment

Wastewater treatment provides significant environmental benefits by protecting water resources and ecosystems. The treatment processes remove pollutants, preventing them from entering the environment and causing harm.The primary environmental benefits include:

- Protection of Water Quality: Wastewater treatment removes pollutants like organic matter, nutrients, and pathogens, preventing them from contaminating rivers, lakes, and oceans. This protects aquatic life and ensures the water is safe for recreational use and other purposes.

- Reduction of Waterborne Diseases: By removing pathogens, wastewater treatment significantly reduces the risk of waterborne diseases, such as cholera, typhoid fever, and dysentery. This protects public health.

- Prevention of Eutrophication: Wastewater treatment removes excess nutrients, such as nitrogen and phosphorus, that can cause eutrophication in water bodies. Eutrophication leads to algal blooms, which deplete oxygen and harm aquatic life.

- Protection of Aquatic Ecosystems: By removing pollutants, wastewater treatment protects aquatic ecosystems from damage. This includes protecting fish, plants, and other organisms that depend on clean water.

- Potential for Water Reuse: Treated wastewater can be reused for various purposes, such as irrigation, industrial cooling, and even potable water in some cases. This conserves water resources.

- Reduction of Odor and Nuisance: Wastewater treatment processes also help to reduce odors and other nuisances associated with untreated wastewater.

Flowchart Illustrating the Stages of Wastewater Treatment

The following flowchart illustrates the typical stages of wastewater treatment, from influent to effluent. The process is a simplified representation of a municipal wastewater treatment plant.[Imagine a flowchart here. It should include the following stages and processes, visually connected with arrows indicating the flow of water. The descriptions below are what should be illustrated in the flowchart’s boxes, and the connecting arrows should indicate the sequence of these stages.

The flowchart starts with “Influent (Raw Wastewater)” and ends with “Effluent (Treated Wastewater)”.]

- Influent (Raw Wastewater): The untreated wastewater entering the treatment plant.

- Preliminary Treatment:

- Screening: Removal of large debris (e.g., trash, rags).

- Grit Removal: Removal of grit and sand.

- Primary Treatment:

- Primary Sedimentation: Settling of solids.

- Sludge Removal: Solids are removed.

- Secondary Treatment:

- Aeration: Oxygen added to support microbial growth.

- Biological Treatment (e.g., Activated Sludge, Trickling Filter): Microorganisms consume organic matter.

- Secondary Clarification: Settling of microorganisms and remaining solids.

- Tertiary Treatment (Optional):

- Filtration: Removal of remaining suspended solids.

- Disinfection: Killing of pathogens (e.g., chlorination, UV).

- Nutrient Removal: Removal of nitrogen and phosphorus.

- Effluent (Treated Wastewater): The treated wastewater ready for discharge or reuse.

Regulations and Compliance

Understanding and adhering to regulations regarding grease and wastewater disposal is crucial for environmental protection and avoiding legal repercussions. Compliance ensures that harmful substances are not released into the environment, protecting water resources and public health. Failure to comply can lead to significant penalties, including fines and legal action. This section provides an overview of the regulatory landscape, permit requirements, penalties, and the importance of record-keeping.

Federal, State, and Local Regulations Governing Grease and Wastewater Disposal

The disposal of grease and wastewater is governed by a complex web of regulations at various levels of government. These regulations aim to protect water quality, prevent pollution, and ensure public health.

- Federal Regulations: The Environmental Protection Agency (EPA) plays a significant role in regulating wastewater and grease disposal through the Clean Water Act (CWA). The CWA sets national standards for wastewater discharges and requires permits for facilities that discharge pollutants into navigable waters. The EPA also provides guidance and support to state and local governments in implementing these regulations.

- State Regulations: States often have their own environmental agencies that oversee wastewater and grease disposal. These agencies may adopt stricter standards than the federal government, depending on local environmental conditions and priorities. State regulations often cover areas such as permitting, pretreatment requirements, and inspection programs.

- Local Regulations: Local governments, such as cities and counties, also have a role in regulating wastewater and grease disposal. These regulations may focus on specific issues, such as sewer use ordinances, which restrict the types and amounts of pollutants that can be discharged into the municipal sewer system. Local health departments may also have regulations related to grease trap maintenance and disposal.

Permits and Licenses Required for Waste Disposal

Obtaining the necessary permits and licenses is a fundamental requirement for legally disposing of grease and wastewater. The specific requirements vary depending on the type of business, the volume of waste generated, and the location.

- Industrial Wastewater Discharge Permits: Facilities that discharge wastewater into a municipal sewer system or directly into a water body typically require an industrial wastewater discharge permit. This permit Artikels the specific limits on the types and amounts of pollutants that can be discharged.

- Grease Trap/Interceptor Permits: Restaurants and other food service establishments are often required to obtain permits for their grease traps or interceptors. These permits may specify requirements for the size, installation, and maintenance of the grease traps, as well as the frequency of waste removal and disposal.

- Solid Waste Disposal Permits: Businesses that generate solid waste, including grease trap waste, may need a solid waste disposal permit. This permit ensures that the waste is disposed of at an approved facility, such as a landfill or a wastewater treatment plant.

- Hauler Permits: Companies that transport grease trap waste or other wastewater often need to obtain a hauler permit. This permit ensures that the hauler has the proper equipment and training to transport the waste safely and legally.

Penalties for Non-Compliance with Disposal Regulations

Failure to comply with grease and wastewater disposal regulations can result in significant penalties, including financial fines, legal action, and reputational damage. The severity of the penalties depends on the nature and extent of the violation.

- Financial Penalties: Fines for non-compliance can range from hundreds to thousands of dollars, depending on the severity of the violation and the specific regulations. Repeated violations often result in higher fines.

- Legal Action: In cases of serious or repeated violations, regulatory agencies may pursue legal action against the responsible parties. This can include lawsuits, injunctions, and even criminal charges.

- Permit Suspension or Revocation: Regulatory agencies have the authority to suspend or revoke permits for non-compliance. This can effectively shut down a business until the violations are corrected and the permit is reinstated.

- Reputational Damage: Businesses that are found to be in violation of environmental regulations may suffer reputational damage. This can lead to a loss of customers, difficulty attracting investors, and a decline in overall business performance.

The Importance of Maintaining Accurate Records of Waste Disposal

Maintaining accurate records of waste disposal is essential for demonstrating compliance with regulations and tracking waste management practices. These records provide a valuable audit trail and can help businesses identify and address potential problems.

- Tracking Waste Generation: Records of waste disposal can help businesses track the amount of waste they generate over time. This information can be used to identify trends, optimize waste management practices, and reduce waste generation.

- Demonstrating Compliance: Accurate records serve as proof of compliance with regulations. They can be used to demonstrate that waste is being disposed of properly and that all required permits are in place.

- Facilitating Audits and Inspections: Regulatory agencies may conduct audits and inspections to ensure compliance with environmental regulations. Accurate records make it easier for businesses to respond to these audits and inspections.

- Identifying and Addressing Problems: Records can help businesses identify and address potential problems in their waste management practices. For example, they can be used to track the performance of grease traps and identify areas where improvements are needed.

Key Regulatory Information in a 4-Column HTML Table

The following table summarizes key regulatory information related to grease and wastewater disposal. This table provides a concise overview of the regulations, permit requirements, and potential penalties.

| Regulation Type | Governing Body | Key Requirements | Potential Penalties |

|---|---|---|---|

| Clean Water Act (CWA) | U.S. Environmental Protection Agency (EPA) | National standards for wastewater discharges; permit requirements for discharges into navigable waters. | Fines, legal action, permit suspension/revocation. |

| State Environmental Regulations | State Environmental Agencies | Permitting, pretreatment requirements, inspection programs; may adopt stricter standards than federal regulations. | Fines, legal action, permit suspension/revocation. |

| Local Sewer Use Ordinances | Local Governments (Cities, Counties) | Restrictions on the types and amounts of pollutants discharged into the municipal sewer system. | Fines, legal action, sewer service interruption. |

| Grease Trap/Interceptor Permits | Local Health Departments/Environmental Agencies | Requirements for grease trap size, installation, maintenance, and waste disposal frequency. | Fines, permit suspension/revocation, business closure. |

Best Practices for Grease Management

Proper grease management is crucial for protecting our environment, maintaining healthy plumbing systems, and ensuring regulatory compliance. Implementing best practices not only minimizes the negative impacts of grease but also can lead to cost savings and sustainable operations. This section Artikels key strategies for effective grease management.

Strategies for Reducing Grease Generation at the Source

Reducing grease at the source is the most effective way to manage it. This proactive approach minimizes the amount of grease entering the wastewater system, preventing clogs and reducing the need for extensive treatment.Here are some effective strategies:* Implement a Dry Waste Program: Encourage employees and residents to scrape food scraps and grease into the trash before washing dishes. This simple step can significantly reduce the amount of grease entering the drains.* Use Strainers and Traps: Install strainers in sinks and drains to capture solid food particles before they can enter the wastewater system.

For commercial kitchens, grease traps are essential for separating grease from wastewater.* Educate and Train: Provide regular training to employees and residents on proper food handling and grease disposal practices. This includes emphasizing the importance of dry scraping, using strainers, and avoiding pouring grease down the drain.* Modify Cooking Practices: Consider alternative cooking methods that generate less grease, such as baking, broiling, or steaming instead of frying.* Optimize Dishwashing Procedures: Ensure that dishwashers are properly maintained and operated to minimize grease accumulation.

Use appropriate detergents and water temperatures.

Examples of Sustainable Practices for Managing Grease

Sustainable grease management goes beyond simply disposing of grease; it focuses on reducing environmental impact and promoting resource recovery.Here are examples of sustainable practices:* Grease Recycling: Collect used cooking oil and grease for recycling. This grease can be converted into biodiesel, a renewable fuel source, or used in other industrial applications.* Composting: Food scraps and grease can be composted to create nutrient-rich soil amendments.

This reduces waste and provides a valuable resource for agriculture and landscaping.* Anaerobic Digestion: Utilize anaerobic digestion to convert grease and food waste into biogas, a renewable energy source, and digestate, a fertilizer.* Partnering with Waste Management Companies: Collaborate with waste management companies that specialize in grease collection and recycling to ensure responsible and efficient disposal.* Implementing a “Fryer Management Program”: For restaurants, a fryer management program can optimize oil usage, reduce waste, and facilitate recycling.

This may include regular oil filtration, monitoring oil quality, and using the correct oil for the food being prepared.

Benefits of Recycling Grease and Wastewater

Recycling grease and wastewater offers numerous benefits for the environment, businesses, and the community.These benefits include:* Environmental Protection: Recycling grease reduces the amount of grease entering wastewater systems and waterways, preventing pollution and protecting aquatic ecosystems.

Production of Renewable Energy

Grease can be converted into biodiesel, a sustainable and renewable fuel source that reduces reliance on fossil fuels and lowers greenhouse gas emissions.

Waste Reduction

Recycling grease diverts waste from landfills, conserving landfill space and reducing the environmental impact of waste disposal.

Economic Benefits

Recycling grease can generate revenue for businesses through the sale of used cooking oil.

Compliance with Regulations

Recycling grease helps businesses comply with local and federal regulations regarding grease disposal.

Creation of New Products

Grease can be used to manufacture various products, including soaps, cosmetics, and animal feed.

Demonstrating Proper Labeling and Storage of Grease Containers

Proper labeling and storage of grease containers are essential for safety, compliance, and efficient recycling. Clear and accurate labeling helps prevent spills, ensures the correct handling of the material, and facilitates the recycling process.* Container Labeling:

Clearly label all grease containers with the following information

“Used Cooking Oil” or “Used Grease”

Date of collection

Source of the grease (e.g., restaurant name)

Contact information of the responsible party

Use waterproof and durable labels that can withstand exposure to the elements.

* Storage Guidelines:

Store grease containers in a designated area away from food preparation areas and potential sources of ignition.

Keep containers tightly sealed to prevent spills and odors.

Protect containers from extreme temperatures and direct sunlight.

Place containers on a level surface to prevent tipping.

Ensure the storage area is well-ventilated.

Consider using secondary containment, such as a spill berm, to contain any potential spills.

* Example Label: Imagine a label on a 55-gallon drum filled with used cooking oil from “Joe’s Diner.” The label clearly states “Used Cooking Oil,” the date of the last collection, the restaurant’s name and contact information, and a warning to keep the container closed. The drum is stored inside a covered area on a concrete pad with a containment berm.

Do’s and Don’ts for Proper Grease Management

Following these “Do’s and Don’ts” will help ensure effective grease management and prevent environmental and operational issues.* Do’s:

Do scrape food scraps and grease into the trash before washing dishes.

Do use strainers in sinks and drains.

Do properly maintain and clean grease traps.

Do recycle used cooking oil.

Do train employees on proper grease disposal practices.

Do label and store grease containers correctly.

Do follow local regulations regarding grease disposal.

* Don’ts:

Don’t pour grease down the drain.

Don’t flush grease down the toilet.

Don’t put food scraps down the garbage disposal.

Don’t dispose of grease in storm drains.

Don’t mix grease with other waste materials.

Don’t store grease containers improperly.

Don’t ignore local regulations regarding grease disposal.

Dealing with Specific Scenarios

Dealing with grease and wastewater issues requires proactive measures and a clear understanding of how to respond to various situations. This section provides guidance on handling grease spills, sewer backups, reporting incidents, flood cleanup, and environmental concerns, ensuring you’re well-equipped to manage these challenges effectively.

Handling Grease Spills in Residential Settings

Grease spills in residential settings, while often small, can pose slip hazards and clog drains if not addressed promptly. Proper cleanup and disposal are essential to prevent further problems.

- Assess the Spill: Determine the size and location of the spill. Identify any potential hazards, such as slippery surfaces.

- Contain the Spill: Use absorbent materials like paper towels, cat litter (unscented), or baking soda to soak up the grease. Avoid using water, as it can spread the grease.

- Absorb the Grease: Carefully apply the absorbent material to the spill, starting from the edges and working inward. Allow the absorbent to sit for a sufficient amount of time to soak up the grease completely.

- Collect and Dispose of the Absorbent: Once the absorbent has soaked up all the grease, sweep or wipe it up and place it in a sealed plastic bag. Dispose of the bag in the trash, not down the drain.

- Clean the Affected Area: After removing the grease, clean the affected area with warm, soapy water to remove any remaining residue and prevent staining.

- Prevent Future Spills: Practice safe cooking habits, such as carefully pouring grease into a container for disposal and avoiding overfilling cooking pots.

Dealing with Grease-Related Sewer Backups

Grease is a major contributor to sewer backups, which can cause significant damage and health hazards. Understanding how to address these situations is crucial for protecting your property and health.

- Recognize the Signs: Be aware of signs of a sewer backup, such as slow-draining sinks and toilets, gurgling sounds in the plumbing, and sewage odors.

- Contact a Plumber: If you suspect a grease-related sewer backup, contact a professional plumber immediately. They can diagnose the problem and provide appropriate solutions.

- Avoid Using Plumbing Fixtures: While waiting for the plumber, avoid using any plumbing fixtures to prevent further backups and potential damage.

- Document the Damage: Take photographs or videos of any damage caused by the backup for insurance purposes.

- Clean and Disinfect: Once the backup is resolved, clean and disinfect any areas affected by sewage to eliminate bacteria and prevent health risks. Wear protective gear, such as gloves and a mask, during the cleaning process.

- Prevent Future Backups: Follow proper grease disposal methods, avoid flushing grease down the drain, and consider installing a grease trap if you frequently cook with grease.

Reporting Grease-Related Incidents to the Appropriate Authorities

Reporting grease-related incidents is essential for ensuring public health and environmental protection. It allows authorities to investigate problems and take corrective actions.

- Identify the Incident: Determine the nature of the incident, such as a spill, a sewer backup, or illegal dumping.

- Gather Information: Collect as much information as possible, including the location, time, and extent of the incident.

- Contact the Relevant Authorities: Report the incident to the appropriate authorities, such as the local health department, the environmental protection agency (EPA), or the wastewater treatment plant.

- Provide Detailed Information: Provide a clear and concise description of the incident, including any relevant details, such as the source of the grease and any potential environmental impact.

- Follow Up: Keep records of your report and follow up with the authorities to ensure the incident is addressed properly.

Procedures for Cleaning Up and Disposing of Grease After a Flood

Flooding can carry grease and contaminate surfaces, posing health risks and requiring specific cleanup procedures.

- Safety First: Prioritize safety by wearing protective gear, including gloves, boots, and a mask, to prevent contact with contaminated water and surfaces.

- Remove Standing Water: Remove any standing water from the affected area using pumps or other appropriate equipment.

- Remove Contaminated Items: Discard any items that have been in contact with floodwater, such as food, paper products, and porous materials that cannot be thoroughly cleaned and disinfected.

- Clean and Disinfect Surfaces: Clean all surfaces that have come into contact with floodwater with a disinfectant solution. Follow the manufacturer’s instructions for use.

- Ventilate the Area: Ensure proper ventilation by opening windows and doors to allow the area to dry completely.

- Properly Dispose of Contaminated Waste: Dispose of all contaminated waste in accordance with local regulations. This may involve contacting a hazardous waste disposal service.

Steps to Take When Discovering a Grease-Related Environmental Issue

Discovering a grease-related environmental issue, such as a spill in a waterway, requires immediate action to mitigate the impact.

- Assess the Situation: Determine the source and extent of the environmental issue. Identify any potential hazards or risks.

- Contain the Spill: If possible, contain the spill to prevent further spread. Use absorbent booms or other containment devices.

- Contact the Authorities: Report the incident to the appropriate environmental authorities, such as the EPA or local environmental agencies.

- Document the Incident: Take photographs or videos of the incident to document the damage and assist with the investigation.

- Cooperate with Authorities: Cooperate fully with the authorities during the investigation and cleanup process. Provide any information or assistance requested.

- Implement Remediation Measures: Follow the guidance of the authorities and implement appropriate remediation measures, such as removing contaminated soil or water.

The Future of Grease and Wastewater Management

The field of grease and wastewater management is constantly evolving, driven by the need for more efficient, sustainable, and environmentally friendly practices. Technological advancements and innovative approaches are reshaping how we handle these critical waste streams, leading to a future where resources are conserved, and environmental impact is minimized. This section explores the cutting-edge developments and future possibilities in this dynamic area.

Latest Advancements in Grease and Wastewater Treatment Technologies

Significant progress is being made in developing more effective and sustainable technologies for treating grease and wastewater. These advancements focus on improving efficiency, reducing environmental impact, and recovering valuable resources.

- Advanced Oxidation Processes (AOPs): AOPs utilize powerful oxidants like ozone and hydrogen peroxide, often combined with UV light, to break down complex organic pollutants in wastewater, including grease. These processes are particularly effective in removing contaminants that are resistant to conventional treatment methods.

- Membrane Filtration: Membrane technologies, such as ultrafiltration and reverse osmosis, are becoming increasingly sophisticated. They offer high-efficiency separation of grease and other solids, producing cleaner effluent and concentrating the waste for further processing or disposal.

- Bioaugmentation: This involves adding specific microorganisms to wastewater treatment systems to enhance the breakdown of grease and other organic matter. This approach can improve the efficiency of existing treatment plants and reduce the need for chemical additives.

- Anaerobic Digestion: This process, already in use, continues to evolve. Advances focus on optimizing digester design, increasing biogas production, and improving the efficiency of converting grease and other organic waste into energy and fertilizer.

Innovative Approaches to Grease Recycling

Recycling grease is moving beyond simple disposal, with innovative approaches transforming it into valuable resources. These methods not only reduce waste but also contribute to a circular economy.

- Biodiesel Production: Grease, particularly used cooking oil (UCO), is a primary feedstock for biodiesel production. The process involves transesterification, where the triglycerides in the grease are reacted with alcohol (typically methanol) to produce biodiesel and glycerol.

Biodiesel production: Triglycerides + Methanol -> Biodiesel + Glycerol

- Biogas Production: Anaerobic digestion of grease can produce biogas, a renewable energy source primarily composed of methane. This biogas can be used for heating, electricity generation, or as a transportation fuel.

- Animal Feed Production: In some cases, treated grease can be used as a component in animal feed, reducing the reliance on other feedstocks and providing a sustainable disposal option. Regulations and safety standards are critical in this application.

- Specialty Chemicals and Bio-Based Products: Research is ongoing to utilize grease as a feedstock for producing various bio-based products, including lubricants, surfactants, and other specialty chemicals. This expands the potential value of grease beyond energy production.

The Role of Technology in Monitoring and Managing Grease

Technology plays a crucial role in monitoring and managing grease, enabling more efficient and proactive waste management practices. Real-time data and automated systems are improving operational efficiency and compliance.

- Smart Monitoring Systems: Sensors and monitoring devices are being deployed in grease traps and wastewater systems to continuously monitor grease levels, flow rates, and other critical parameters. This data provides early warnings of potential problems, such as blockages or overflows.

- Remote Monitoring and Control: Operators can remotely monitor and control wastewater treatment plants and grease management systems using advanced software and communication technologies. This allows for real-time adjustments and optimization of processes.

- Data Analytics and Predictive Maintenance: Data collected from monitoring systems is analyzed to identify trends, predict potential equipment failures, and optimize maintenance schedules. This helps to reduce downtime and improve operational efficiency.

- GIS Mapping and Tracking: Geographic Information Systems (GIS) are used to map and track grease collection and disposal operations, optimizing routes, and ensuring compliance with regulations.

The Potential of Biofuels Derived from Waste Grease

Biofuels derived from waste grease, especially biodiesel, represent a significant opportunity for sustainable energy production. This reduces reliance on fossil fuels and contributes to a circular economy.

- Biodiesel as a Transportation Fuel: Biodiesel can be used in existing diesel engines, making it a readily available alternative to conventional fuels. The environmental benefits include reduced greenhouse gas emissions and a lower carbon footprint.

- Blending with Conventional Diesel: Biodiesel can be blended with conventional diesel fuel to reduce its environmental impact. Common blends include B5 (5% biodiesel) and B20 (20% biodiesel).

- Economic Benefits: Biodiesel production creates jobs and supports local economies. The use of waste grease as a feedstock provides a cost-effective and sustainable alternative to virgin vegetable oils.

- Regulatory Support: Government incentives and mandates, such as the Renewable Fuel Standard (RFS) in the United States, encourage biodiesel production and use. These policies drive the growth of the biodiesel industry.

Visual Representation of the Future of Grease Management

The future of grease management can be visualized as an interconnected, closed-loop system, characterized by sustainability, efficiency, and resource recovery.

Imagine a circular diagram. The center of the circle is labeled “Grease & Wastewater.” Arrows emanate outwards, representing various stages and technologies:

- Collection and Transportation: Drones or autonomous vehicles equipped with smart sensors collect grease from restaurants and other sources. These vehicles optimize routes using GPS and real-time data, ensuring efficient and timely collection.

- Pre-treatment: At a centralized facility, advanced pre-treatment systems, including filtration and separation technologies, remove solids and contaminants from the grease and wastewater.

- Treatment:

- Wastewater Treatment: Advanced oxidation processes (AOPs) and membrane filtration systems treat wastewater, removing pollutants and producing clean water for reuse or safe discharge.

- Grease Processing: The collected grease is directed towards two main pathways:

- Biodiesel Production: A dedicated facility uses transesterification to convert grease into biodiesel, a renewable fuel source.

- Anaerobic Digestion: Grease is fed into anaerobic digesters to produce biogas, a renewable energy source used to power the facility or injected into the natural gas grid.

- By-product Utilization:

- Glycerol: A by-product of biodiesel production is refined and used in various industries, such as pharmaceuticals and cosmetics.

- Digestate: The solid residue from anaerobic digestion is composted and used as a soil amendment in agriculture.

- Monitoring and Control: A central control system monitors all aspects of the process, using real-time data from sensors and smart technologies. This system optimizes efficiency, ensures compliance, and allows for remote management.

- Sustainability and Resource Recovery: The entire system is designed to minimize waste, recover valuable resources, and reduce environmental impact. The clean water, biodiesel, biogas, and other by-products contribute to a circular economy, closing the loop and minimizing the need for virgin resources.

This visual representation highlights a future where grease and wastewater are not viewed as waste but as valuable resources, contributing to a more sustainable and environmentally responsible world.

Conclusion

In conclusion, mastering the proper disposal of grease and wastewater is more than just a matter of compliance; it’s a commitment to environmental stewardship. By understanding the processes, regulations, and best practices Artikeld in this guide, you can significantly reduce your impact, prevent costly problems, and contribute to a sustainable future. Remember, responsible disposal is a collective effort, and every action counts.